The starting point is the general mapping of the project, an overall vision of the objectives that must be defined and constantly monitored during the entire design process. In this phase we will mainly explore the market, the positioning, the initial costs, the requirements and the technical feasibility of the new product.

Markets, Competitors, Positioning, Requirements, Features, Usability, Uniqueness, Costs

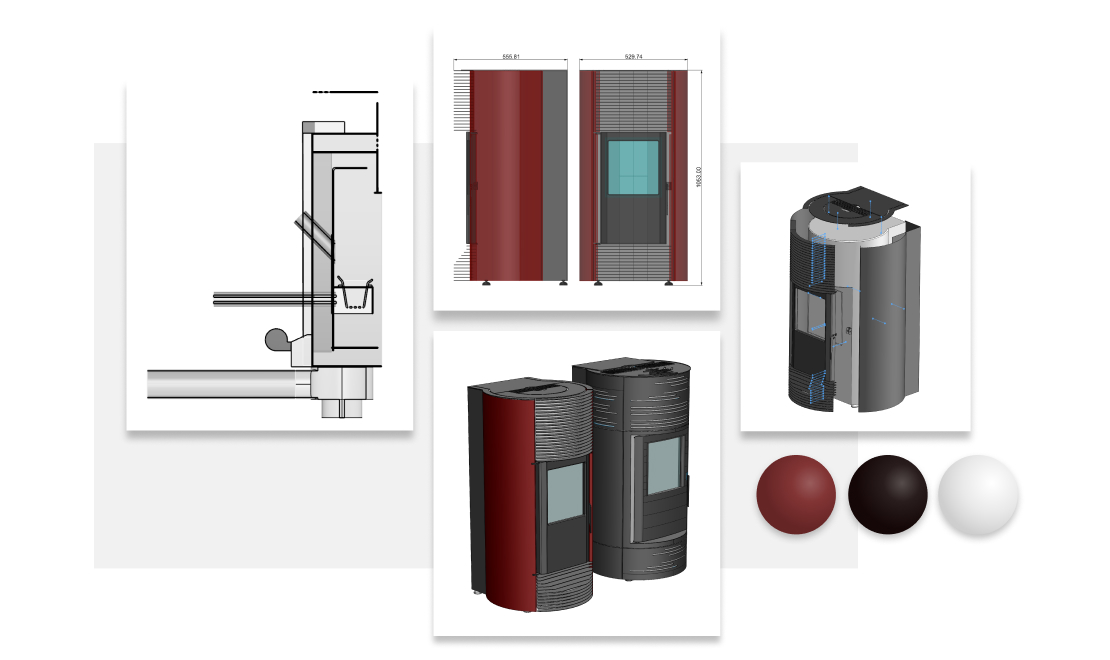

In this phase the new product takes shape starting from the general mapping. Fron the first drafted aesthetic lines the overall style and functional details of the new product take shape. The initial draft of the technical parts and stylistic elements is translated into a 3D model taking into account the assembly process, the materials and the requirements of the relevant legislation.

Concept, Components, Style, Layout, Materials, Assemnling, Standarts, M.V.P

Once the Design is defined, we move on to the technical development in order to make the new product manufacturable. This phase involves the development of all the parts that make up the product: structural parts, mechanisms, and aesthetic coatings with the creation of engineered 3D models and technical boards of each component and its respective assemblies. The most complex design solutions are verified through virtual simulations.

Geometry, Engineering, Mechanisms, Kinematics, Tolerances, Virtual simulation, Technical drawings

Once the Development phase is completed, we move on to the construction of the first prototype to carry out real functioning tests of the new product at laboratories and certification bodies.

Functional protoype

Once the test data have been collected, we proceed with the product refinement phase, therefore with the necessary modifications of the engineered 3D models and the technical boards that will be the final ones used for manufacturing.

Fine tuning, Assessment, Validation

Final certification phase of the product and construction of manufacturing equipments for production.

Tooling, Certification