Frandent Air Swather is a project designed by ZAAFDesign with Agroingegno and Phitec Ingegneria. The swather uses an innovative horizontal movement system to reduce swath deterioration during harvesting.

The swathing or windrowing is an operation carried out in the field of haymaking which consists in moving the cut forage, to collect it in heaps called windrows or swaths. It is perfomed with mechanical agricultural machines – windrowers or swathers – which simulate and replace the manual use of the rake.

During haymaking, the risk of crop deterioration due to the mechanical movements of the machine is very high and it must be limited as much as possible, especially when there are herbaceous crops that require particular attention, such as alfalfa, for example.

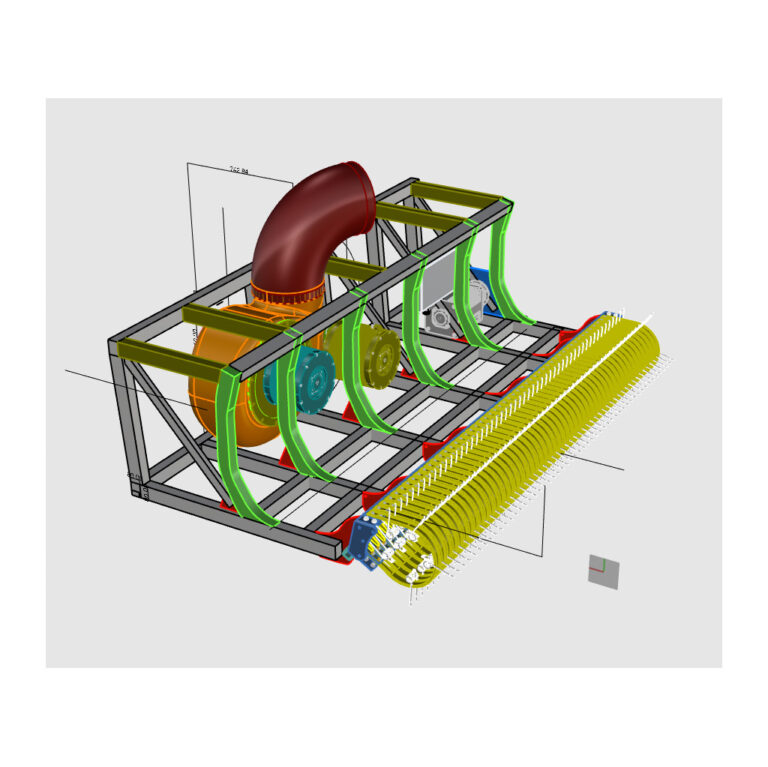

The challenge in this agricultural industry was to conceive a new innovative system for mechanical agricultural machines, using an extremely delicate element for horizontal movement: air. After lifting to the plane of the “air bed”, the product is pushed transversely by the air without creating breakage on leaves and stems.

With a multidisciplinary team made up of Agronomists, Product Designers, Mechatronic-CFD-Electronic Engineers and Electrotechnicians who are experts in the BUS systems integrated into the new tractors, the project developed into the following phases:

Study and analysis of the lifting chamber both on a virtual and on a real level through the first static test. Thanks to the analysis and collection of data and knowledge resulting from very different and strongly connected skills, it was possible to create a database for the creation of the final prototype.

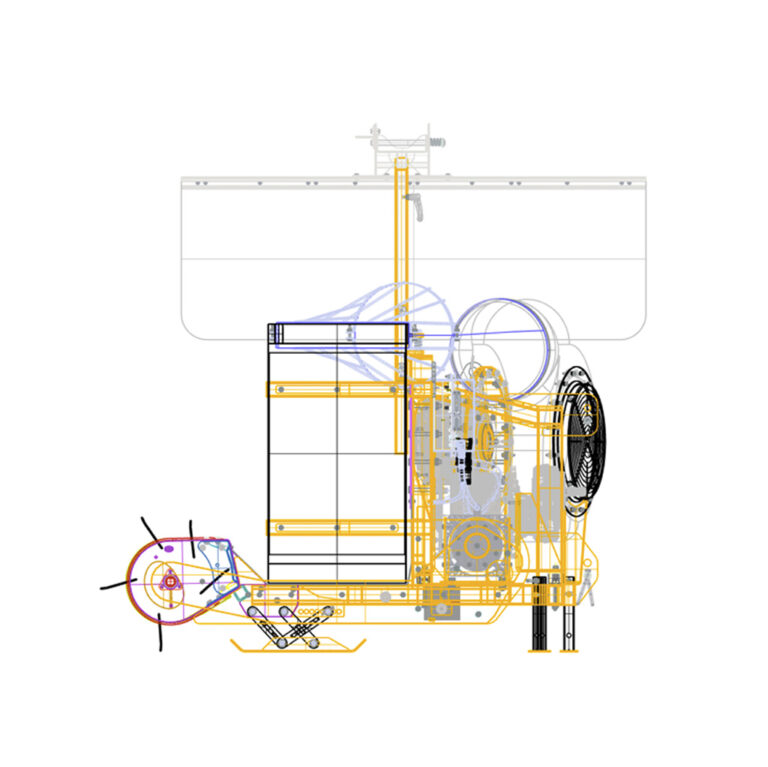

For the definition of the prototype to be used in the dynamic tests in the field with the relative organization of the tests themselves. The field tests made it possible to observe not only the functioning of the chamber but also the uses of a generic operating machine, from a purely structural point of view, collecting important data for the third sub-service.

The last step of the design process for the production of the final machine.

The fact that there were fans in production suitable for the needs highlighted by the CFD analyses, equipped with electric motors, also prompted us to revise the rest of the machine with an increasingly electric imprint, in order to eliminate in the future the characteristic mechanical connection between the tractor and machine through electric cables and a BUS control cable as a possible connection hypothesis.

An important paradigm shift that projected the project into the future of fully electric agricultural machinery.

The air windrower designed for Frandent is in fact placed in a context in which the design of agricultural machinery is evolving today to conceive machines controlled as much as possible by electric motors: more performing, with a significant reduction in wear and materials consumption and – consequently – also maintenance costs.